Copper Mountain Mining Corp., (TSX:CMMC), NI 43 101, May 7th, 2020

- Eva Copper PFS iron oxide copper-gold deposits Update, North West Queensland, Australia

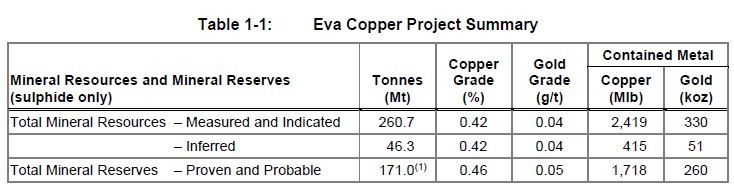

- Reserves Au 260 kOz

- Reserves Cu 1718 Mlb

- Resources Au 381 kOz

- Resources Cu 2834 Mlb

EXECUTIVE SUMMARY

The Eva Copper Project (the Project) is 100% owned by Copper Mountain Mining Corporation

(CMMC, or the Company) through a wholly-owned subsidiary Copper Mountain Mining Pty. Ltd.

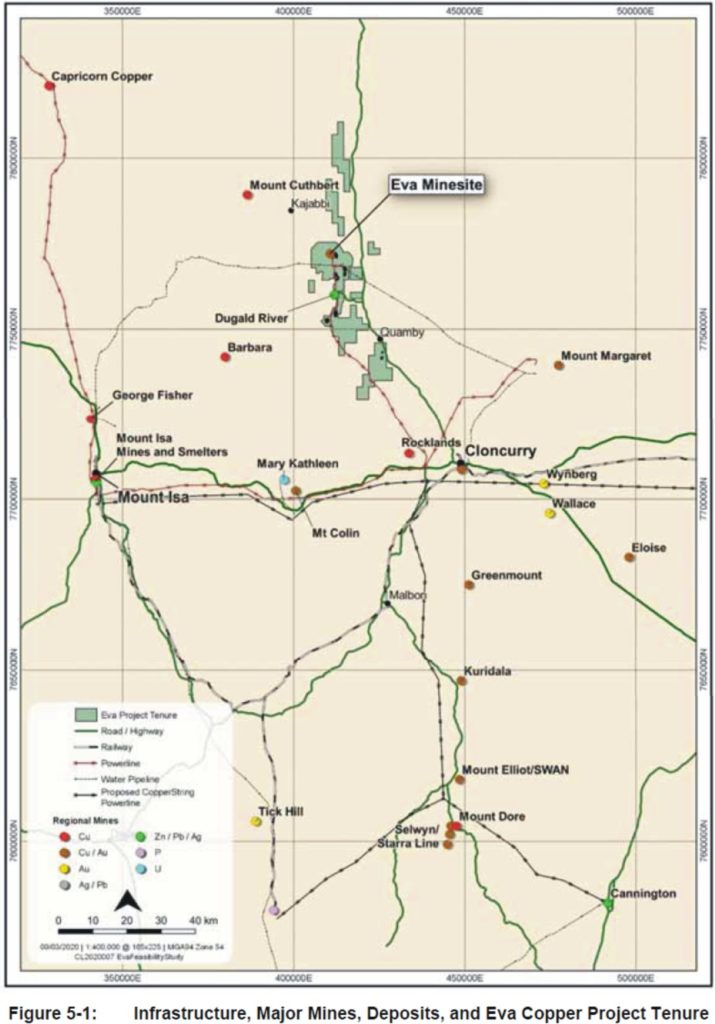

(CMMPL). The Project is in North West Queensland, approximately 76 kilometres (km) northwest of

Cloncurry, and 194 km northeast of Mount Isa.

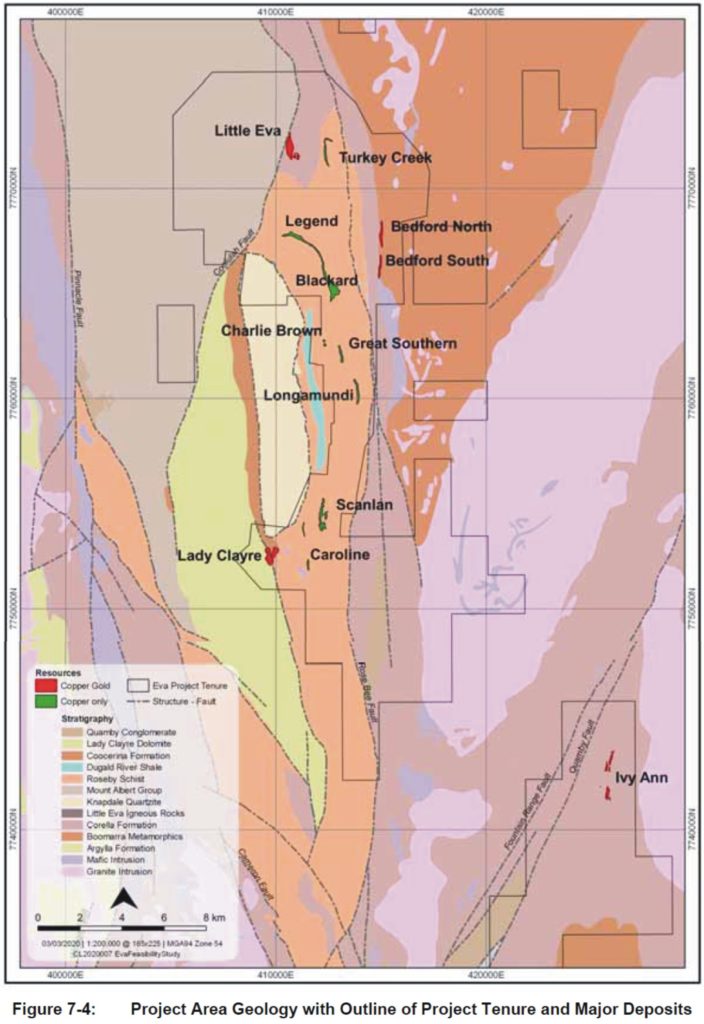

The Eva Copper Project is anticipated to mine 170 million tonnes (Mt) of ore and 381 Mt of waste

from seven open pit deposits, with a minimum projected mine life of 15 years. The seven deposits in

order of size are Little Eva, Blackard, Scanlan, Turkey Creek, Lady Clayre, Bedford, and Ivy Ann.

Mineral Reserves will be mined using conventional earthmoving equipment, and will be hauled to a

processing plant by way of haul roads from each pit. Waste material will be stacked in waste dumps

adjacent to each pit, except for some material that will be used to construct the tailings storage facility

(TSF) and bund walls around the open pits.

The processing plant will process 11.4 million tonnes per annum (Mt/a), operating at 31,200 tonnes

per day (t/d), through a conventional crushing, high pressure grinding rolls (HPGR), milling, gravity,

and flotation plant, for the fifteen-year life-of-mine (LOM) duration.

Existing major infrastructure closely surrounding the Project site includes the Burke Developmental

Road, located 8.5 km to the east of the Project, which connects Cloncurry with Normanton. A power

transmission line installed by MMG Limited (MMG)’s Dugald River mine is located 11 km south of the

Project. A water pipeline that runs from Lake Julius to the Ernest Henry Mine traverses the southern

portion of the Project site. A residential area, known as the Mount Roseby Homestead, is located

approximately 17.5 km to the south of the Project plant site. Current infrastructure located on the

Project site itself is minor, and includes dirt tracks for exploration, water points, and fences.

Major infrastructure required to be developed for the Project includes:

- Processing plant, workshops, laboratory, administration, security, and training offices

- Seven open pit mines, pit dewatering, diversion channels, and bund walls

- Tailings Storage Facility

- An 11 km, 220 kV power transmission line from the Dugald River mine

- An employee accommodation village to house 300 personnel

- New intersection from the Burke Developmental Road, an 8.5 km-long site access road, and haul

- roads

- Water wells at Little Eva, Blackard, and approximately 2 km north of the Little Eva pit

- Telecommunications infrastructure.

1 Key Facts

Units of measurement used in this report conform to the metric system. All currency is United States dollars (US$) unless otherwise noted.

Copper Mountain Mining Pty. Ltd. (CMMPL) is a wholly-owned subsidiary of Copper Mountain Mining Corporation (CMMC, or the Company). CMMPL is located in Queensland, Australia, and was formerly known as Altona Mining Limited (Altona). The Project is located approximately 76 km northwest of Cloncurry in North West Queensland, Australia, and has extensive exploration potential in the approximately 4,000 km2 (379,000 hectare [ha]) mineralized land package. CMMC commissioned Ausenco Limited (Ausenco)to redesign and redevelop the 2018 Feasibility Study process plant and associated site infrastructure, and to provide technical input into the preparation of this National Instrument (NI) 43-101-compliant Feasibility Level Technical Report. In addition, CMMC commissioned Klohn Crippen Berger (KCB) to redesign the 2018 Knight Piésold Ltd. (Knight Piésold) TSF and to provide input to water management, and Merit Consultants International (Merit), a division of Cementation Canada Inc., to develop the capital cost, construction management, and execution plan of the Project. The Project is proposed to be a large, open pit copper-gold mining operation with an associated gravity and flotation processing plant, similar to other operations in the Mount Isa and Cloncurry area. The Project comprises the large Little Eva open pit and six smaller satellite pits, which will deliver a sulphide and native copper ore mixture in a ratio of 75% to 25%, respectively, to a 11.4 Mt/a processing plant adjacent to the Little Eva and Turkey Creek pits.

2 Property Description and Location

The Eva Copper Project is located 76 km northwest by road from Cloncurry, and 194 km northeast by road from Mount Isa, a regional mining centre. Access to the Project is via the sealed Burke Developmental Road from Cloncurry. This road passes 8.5 km to the east of the proposed processing plant site and the Little Eva and Turkey Creek pits. The site is also 11 km north of the major operating Dugald River zinc mine. The Project is 100% owned by CMMC. The planned pits and Mineral Resources are within five granted Mining Leases (ML), except for the Ivy Ann pit, which is within the Exploration Permit for Minerals (EPM) 25760 (King). The MLs total an area of 143 km2, and are situated across from two pastoral lease holdings and within one Native Title grant. There are two freehold lots granted in the late 1800s, and 100% owned by the Company, that lie within the MLs; the first sits over part of the Little Eva deposit, the second over part of the Longamundi deposit. Necessary agreements are secured with the pastoral leaseholders and Native Title party (Kalkadoon People) that set out conduct and compensation terms for the planned mining activities to proceed. Additional third-party agreements and consents have been secured for the Project access road from the Burke Developmental Road. An application has been submitted to the Department of Natural Resources, Mines and Energy (DNRME) for the realignment of the mine access road proposed in the current design. Numerous royalties apply to the Project. Royalties on minerals are payable annually to the Queensland State Government on an ad valorem basis, with various costs being permitted as a deduction from sales revenue. Copper and gold royalty rates vary between 2.5% and 5.0% of value, depending on average metal prices, as per Schedule 3 of the Mineral Resources Regulation of 2003. No state royalty on copper is applicable to the two freehold lots owned by the Company Several royalties also apply to the Project from purchase agreements and are payable to several parties variably across portions of the Project area. These apply to all of the deposits in the Project mine plan: a total 1.5% net smelter return (NSR) royalty is applicable to the Little Eva, Blackard, Scanlan, Turkey Creek, Bedford, and Lady Clayre deposits, and a 2% NSR royalty is applicable to the Ivy Ann deposit. Compensation for the effects of mining activities on the Native Title of the Kalkadoon People has been agreed upon. In addition to the granted MLs, the key environmental and permitting consideration for a mining project in Queensland is the approved Environmental Authority (EA) from the Department of Environment and Science (DES), the administrating authority for the environmental management of the Project.

The Queensland Government introduced rehabilitation and Financial Assurance (FA) reforms subsequent to grant of the current EA and previous Feasibility Study that included the Mineral and Energy Resources (Financial Provisioning) Act 2018 (MERFP Act) that was passed in November 2018. New regulatory requirements result from the reforms and are included here. Key EA regulatory management issues, particularly in the mine development period, are:

- EA Major Amendment application. The current EA is based on a previous 2016 mine layout. Changes to the mine layout will require submission of an EA Major Amendment to the DES. This is a straightforward requirement with application preparation and pre-lodgement meetings.

- Progressive Rehabilitation and Closure (PRC) plan submission. Organizations carrying out mining activities in Queensland are legally obligated to rehabilitate the land. Recent legislation reforms require holders of an existing EA for a mining activity relating to a mining lease approved through a site-specific application granted prior to passage of the PRC plan legislation (as per Eva), to develop and submit a PRC plan to the DES. As mine development at Eva has not commenced, a PRC plan is required to be submitted in conjunction with the proposed EA Major Amendment application.

- Estimated Rehabilitation Cost (ERC) decision. An ERC decision is required to be in effect before commencing any activities under an EA. The ERC is the estimated cost of rehabilitating the land on which a resource activity is carried out, and preventing or minimizing environmental harm, or rehabilitating or restoring the environment in relation to the resource activity. DES is responsible for deciding the ERC for an EA for resource activities. The ERC came into effect in 2019 under the MERFP Act reforms, and replaces the previous Plan of Operations (PoO) requirements.

- ERC scheme Financial Assurance (FA). This is required to be lodged with DES (either as a contribution paid to the scheme fund, or as a surety given under the MERFP Act) prior to any activities being allowed to commence. The amount of the FA required is calculated in accordance with DES procedures, based on the implementation of site-specific rehabilitation and closure tasks, using independent contractor third-party rates. The amount of the FA is directly related to the activities authorized.

- Design plan for the Cabbage Tree Creek diversion. Final detailed plans will need to be formally submitted, and approval received, prior to construction being allowed to commence.

- Environmental offset requirements. The Project triggers the requirement of an offset due to the disturbance of regional ecosystems resulting from the disturbance of Cabbage Tree Creek. There are two options for offsets: a financial settlement, or a proponent-driven offset which may include approved conservation work programs. A series of submissions are required, including Significant Impact Details, Offset Report, and Notice of Election at least four months prior to commencement of any site work (Significant Residual Impacts). To fulfil its obligations, the Company intends to opt for a financial settlement, but is interested in investigating a proponent driven offset (at least in part) involving the rehabilitation of Cabbage Tree Creek utilizing an indigenous contractor.

4 History

The Project has a long history, and has been held under various tenures by a variety of exploration and mining companies. Small-scale mining dating back to the early 1900s has occurred at deposits such as Little Eva, Bedford, and Lady Clayre. Early explorers that contributed significantly to the Project with the discovery of the copper-only or native copper deposits are Ausminda Pty. Ltd., and then CRA Exploration (CRAE), who completed the first substantive work between 1990 and 1996, also defining a small resource at Little Eva. CRAE sold its interest in the Project to Pasminco in 1998. Altona acquired the Project in 2001. Altona purchased the tenement hosting the Ivy Ann deposit from Dominion Metals Pty. Ltd. (Dominion) and Pan Australian Resources NL (PanAust). The remaining property was acquired by purchasing tenure from both Pasminco and Lake Gold Pty. Ltd. in a 50:50 ownership split between Altona and Roseby Copper Pty. Ltd. (RCPL). In 2004, Altona purchased RCPL, and thus Altona held 100% of the Eva Copper Project resources. Until 2009, work focused extensively on the copper-only resources, with completion of two feasibility studies based on blends of sulphide ore and copper-only ore. From 2009 to 2012, Altona carried out additional drilling, resulting in Mineral Resource upgrades at the Little Eva, Bedford, Lady Clayre, Ivy Ann, Blackard, Legend, and Scanlan deposits. Little Eva’s resource estimate was doubled due to the additional drilling. In 2012, Altona completed a Feasibility Study based on the increased resources at the copper-gold sulphide deposits, and excluding the Blackard and Scanlan deposits. Altona published Mineral Reserves for the Little Eva, Bedford, Lady Clayre, and Ivy Ann deposits as part of the 2012 FeasibilityStudy. Altona published updates to the Feasibility Study in 2014 and 2017. The 2017 update

incorporated the subsequently delineated significant Mineral Resource at Turkey Creek. MLs and an EA were granted in 2012 based on the 2009 Feasibility Study mine plan. An EA amendment was granted in 2016 based on the revised 2012 Feasibility Study mine plan and the integration of Turkey Creek into that mine plan; this is the current EA. Altona completed a DFS update in 2017, incorporating the Turkey Creek deposit in the mine plan and significant layout changes that included changes to the size and location of the TSF and a Cabbage Tree Creek diversion channel at Little Eva pit. To support the previous studies, the Little Eva, Bedford, Lady Clayre, and Ivy Ann deposits have had a number of formal Mineral Resource estimates that reflect stages of resource definition dating from 2006 to 2017. The only Mineral Resource estimate for Turkey Creek was completed in 2015. Estimates were largely undertaken by external independent experts, initially by McDonald Speijers, and most recently Optiro, based on data and geological models provided by the Company. CMMC completed a Feasibility Study in September 2018 in which in-house experts for this study produced revised Mineral Resource and Mineral Reserve estimates. No significant resource drilling was completed since the previous published resource update. However, metallurgical data was collected from existing samples and two new drill holes in the Little Eva pit. CMMC commenced this report, a Feasibility Study, in 2019, in which in-house experts for this study produced revised Mineral Resource estimates based on additional data and infill drilling at Blackard. Additional metallurgical data was collected from existing samples and from new drill holes at the Little Eva and Turkey Creek pits.

5 Geological Setting and Mineralization

The Project area is situated within the Mount Isa and North West Region of Queensland, Australia, an area that is one of the premier base metal-bearing areas of Australia, with mining activities having taken place since the discovery of copper and gold near Cloncurry in the 1860s. The Mount Isa areahosts numerous base metal copper, zinc, and lead deposits of global significance, including the Mount Isa, Ernest Henry, Century, Dugald River, Canington, and Selwyn deposits. The Eva Copper Project is hosted by Proterozoic-aged, metamorphosed and poly-deformed marine sedimentary and volcanic rocks of the Mary Kathleen domain of the Eastern Fold Belt Inlier. Deformation, metamorphism, and plutonic activity took place during the Isan Orogeny, approximately 1,600 to 1,500 million years (Ma) ago. There are twelve known mineral deposits in the Project area, of which seven have been included in the current mine plan. Mineral deposits are grouped into two types: copper-gold, and copper only. There are five of the copper-gold deposits, all of which are in the mine plan. These deposits are classified as iron oxide copper-gold (IOCG) deposits, where mineralization is associated with regional-scale hematite and albite alteration (red-rock alteration), and localized magnetite alteration. Copper sulphide mineralization, primarily chalcopyrite with lesser bornite, occurs as veins, breccias, fracture fill, and disseminations in mafic to intermediate volcanic or intrusive rocks. Gold is generally correlated with copper, and is recovered in the copper concentrate. Mineralization appears to be localized and/or bounded by faults and other deformation-related structures. The copper-only deposits are stratabound, locally stratiform, and most occur within metamorphosed calcareous metasedimentary rocks, forming an approximately linear trend stretching over 7 km. The origin of these deposits is uncertain; they may be deformed and metamorphosed versions of sedimentary or red-bed type copper deposits, or they could be more closely related to the IOCG deposits, but with enhanced stratigraphic controls related to the calcareous beds being particularly reactive with hydrothermal fluids. All of the deposits have a 10 m to 25 m thick overlying zone of oxidation, where the rock is extensively weathered, and copper sulphide minerals have been leached or converted to various oxide minerals that cannot be recovered by flotation. The oxide zones are treated as waste, but tonnages and copper grades have been estimated. With the exception of the Turkey Creek deposit, the copper-only deposits commonly have a significant thickness of supergene material, where carbonate has been leached from the rock, reducing hardness and density, and the copper occurs as native-copper, chalcocite, and other low-sulphur copper species. The carbonate-leached zone is separated from the underlying sulphide zone by a thin transition zone. Each of these mineralogical zones has been modelled so that resources can be estimated for each and the appropriate metallurgical recoveries can be applied for reserve estimation.

6 Mineral Resources Estimate

6a Eva Copper Project Resources

Mineral Resource estimates were prepared by CMMC personnel, based on all drilling conducted up to October 2019. The effective date of the resource estimates is January 31, 2020. Only the Little Eva, Turkey Creek, and Blackard deposits have new data, which is limited to two core holes in the Little Eva deposit, one in Turkey Creek, and eighteen RC holes in the Blackard deposit. The new drilling was primarily to obtain material for metallurgical testing, but additionally for the verification of grades in the historical data, and infill drilling at the Blackard deposit. Resource estimates by CMMC have been completed on all deposits within the mine plan. The resource estimates were made using methods and block sizes deemed appropriate for the anticipated mining methods, mining equipment, and grade control methods described in this report. The constraining pit shells for defining the limits of Inferred resources are based on economic values that are, among other inputs, dependent upon metallurgical recoveries which have been determined from work carried out, and described, in this report. Resources were constrained by Whittle pit shells for the Little Eva and Turkey Creek deposits generated using metal prices of $3.50/lb Cu and $1,250/oz Au. Pit shell constraints for the other deposits were generated using metal prices of $3.50/lb for copper and $1,250/oz for gold. A zone of oxidation overlies all of the seven deposits in the Eva Copper Project. The base of the oxidized zone is generally sharp (±2 m), and was modelled during resource estimation. In the current mine plan, the oxidized material is treated as waste, as currently there does not appear to be anyform of economic extraction; however, grades have been modelled and tonnages tabulated for general interest and in the event of possible processing in the future. The tonnage and grade of oxidized material were determined in the same manner and at the same time as the other resource estimations. The two copper-only deposits in the mine plan, Blackard and Scanlan, were not included in CMMC’s previous study, as processing methods and recoveries were uncertain. Metallurgical testing was completed in 2019 on mineralization from the Blackard deposit, which has resulted in determination of a suitable process methodology with reliable recovery estimates, such that these deposits are now included in the mine plan.

6b Other Deposits Historical Resources

In addition to the Blackard and Scanlan deposits, there are five additional copper-only deposits that occur along an approximately linear trend, extending from the Legend deposit in the north to the Lady Clayre deposit in the south. In general, other than Blackard and Scanlan, the historical resource estimates for these deposits are relatively small. However, most of the deposits remain open to expansion, and in particular the Legend deposit, which is the northern extension of the Blackard deposit, is proximal to mine infrastructure. The Company has not estimated resources in these deposits, and the values presented in this Report are historical estimates only.

7 Mineral Reserve Estimate

The Eva Copper Project has a Mineral Reserve of 171 Mt grading 0.46% Cu and 0.05 g/t Au for 1.718 billion pounds (Blb) contained copper, and 260,000 oz contained gold. Approximately 95% of the Mineral Reserve is contained in the Little Eva, Blackard, Scanlan, and Turkey Creek deposits. The Bedford, Lady Clayre, and Ivy Ann satellite deposits compose the remaining 5% of the Mineral Reserves. Little Eva and Turkey Creek will be mined first, and the satellite deposits will supplement the Project’s production in the latter years. Approximately 25% of the mill feed will now be softer native copper ores, originating from the Blackard and Scanlan deposit areas. All deposits have ore tonnages classified as either Proven or Probable Mineral Reserves only, and additional Inferred Mineral Resources are not included in the mine schedule. All Mineral Reserves are classified and reported in accordance with the 2011 CIM Standard. CMMC considers the Mineral Reserve estimate, checked by QP Stuart Collins, P.E., to be reasonable, acceptable, and reported in accordance with CIM definitions and NI 43-101. The Mineral Reserves are generated based on the mine designs applied to the Measured and Indicated Mineral Resources only. The design methodology uses both the cut-off grade estimation and economic assessment to design and validate the Mineral Reserves. CMMC is not aware of any mining, metallurgical, infrastructure, permitting, or other relevant factors that could materially affect the Mineral Reserve estimate. Rounding may result in apparent differences when summing tonnes, grades, and contained metal content. Tonnage and grade measurements are in metric units. Gold grades are reported in grams per tonne (g/t), and copper grades are reported in percent of total copper (%Cu). All oxide material was considered as waste; however, CMMC will take the necessary actions to segregate this material for future processing. George Orr and Associates conducted a full stability analysis of an earlier planned Little Eva pit based on geotechnical analysis of 21 oriented DDHs covering both an earlier starter-pit design and the final pit design utilized in this study. The northwest portion of the deposit has poor to moderate ground conditions; however, the majority of the planned pit ground conditions are good to moderate. Overall slope angles of 43 degrees, inclusive of pit ramps, have been recommended and are used in the Little Eva pit design. The eastern pit wall has the best ground conditions, and therefore all access ramps have been placed on this wall. Pit optimization was completed by CMMC and verified by Stuart Collins, P.E. The metallurgical recoveries used in optimization were derived by GRES and OZMET Metallurgical Consultants (OZMET) from all pre-existing testwork carried out by ALS Ammtec in 2011 and 2012, and updated by CMMC in 2019. Metallurgical, economic, and other assumptions were current in 2017, and were updated by CMMC in 2018. These optimizations formed the basis of pit designs and the Mineral Reserves. The Little Eva mine design includes a 22-m wide dual lane in-pit haul road at a 10% gradient on the east wall of the final pit. The pit is approximately 1,700-m long, 950-m wide, and 310-m deep. Mining dilution was accounted for in the modelling of the larger size blocks (5 m by 5 m by 5 m). This block size reflects the large-scale bulk nature of the deposit. The degree of selectivity in mining is relatively low, and varies in differing domains of the deposit. Little Eva and Turkey Creek Mineral Reserve mine design is based upon a minimum mining unit of 5 m by 5 m by 5 m. Mine equipment has been scaled to allow selective mining for this size. Mineral Reserves will be classified in grade control either as run-of-mine (ROM) feed to be sent directly to the processing plant, marginal ore to be sent to a stockpile for later treatment, or waste. The opportunity exists to improve grade control and reduce unit mining costs. Optimization of the Blackard, Scanlan, Bedford, Lady Clayre, and Ivy Ann deposits was completed using inputs similar to those used at Little Eva; however, it was assumed that fixed costs were covered by the Little Eva mine, and the cost of haulage to the processing plant was added to each of the satellite deposit ore processing costs. The distances from Blackard and Bedford, Scanlan and Lady Clayre, and Ivy Ann to the processing plant located near Little Eva and Turkey Creek are 6 km, 20 km, and 36 km, respectively. Metallurgical testwork on these deposits indicates that metallurgical characteristics and recoveries are not materially different from the Little Eva deposit. Scheduling of

ore extraction from the satellite deposits will mainly commence in Year 3 and continue through the end of the mine life. Marginal material from the satellite pits will be assumed as waste, and will not be transported to the processing plant. Pits at the other satellite deposits were designed to the same level of detail as Little Eva and Turkey Creek, and the contribution of the other satellites (Blackard, Scanlan, Lady Clayre, Bedford, and Ivy Ann) has grown to 45% of the Mineral Reserves. New pit optimizations and designs will be completed as new Mineral Resource estimates and geotechnical models become available during the Project’s development period.

Dodaj komentarz